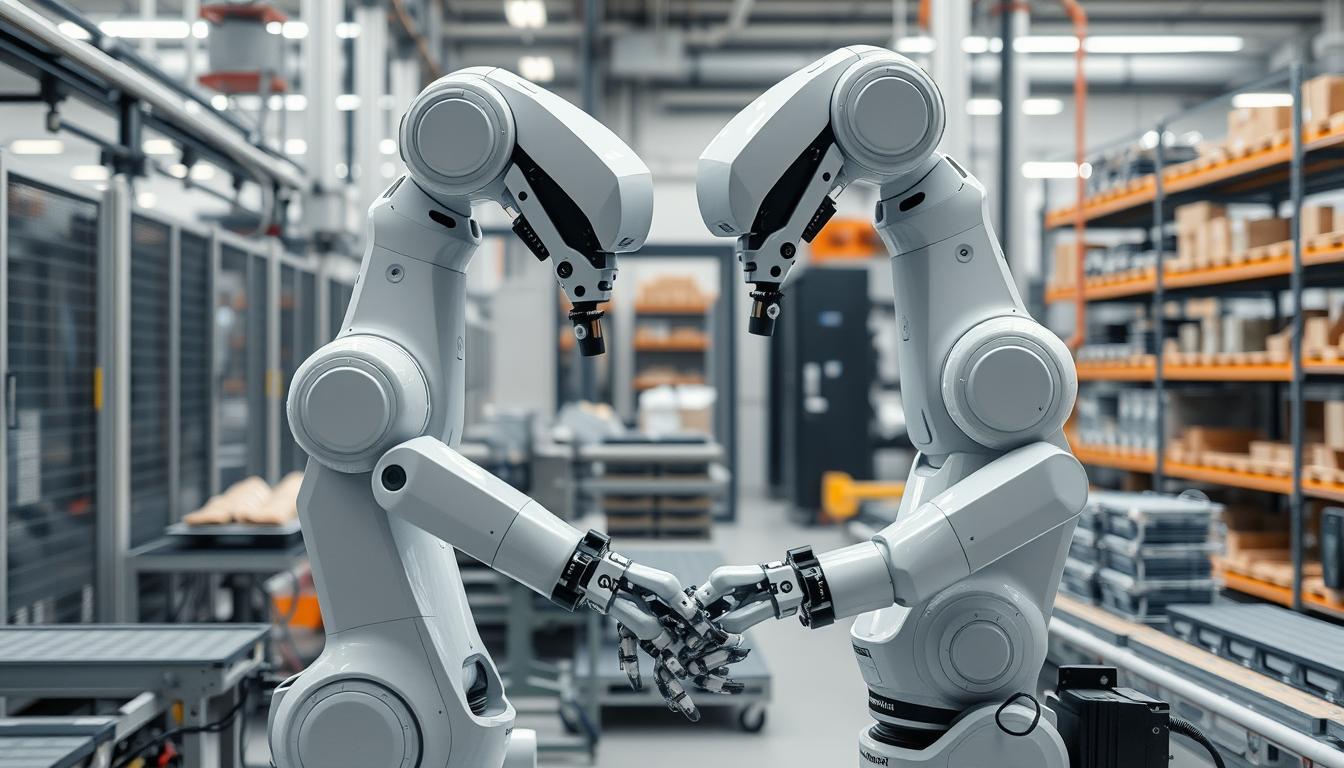

There is a massive shift in the manufacturing industry with the introduction of collaborative robots, also known as cobots, into the factory processes. With the increasing automation of factories, worker safety in conjunction with the new technologies is the most important.

Cobots are planned to collaborate with human workers, which will be more productive and efficient. But when they are introduced into the factory floor, there is a burning question of worker safety and the effectiveness of safety measures that are required.

The changing environment of contemporary production requires a balanced attitude towards the integration of technologies and the safety of workers.

Key Takeaways:

- The manufacturing industry is being transformed by the introduction of cobots.

- The introduction of cobots raises one of the most important issues in worker safety.

- There should be sufficient safety measures to take care of workers.

- It is important to balance between technology and the safety of the workers.

- Cobots make manufacturing more productive and efficient.

The Changing Face of Contemporary Manufacturing:

The use of collaborative robots and factory automation puts modern manufacturing at the edge of a revolution. The change can be defined by the fact that traditional automation is being replaced by smarter and flexible manufacturing processes.

The stable and conventional manufacturing environment has been characterized by inflexible automation systems which though effective, do not offer the ability to adjust to the fluctuating manufacturing requirements. This is however changing with the introduction of smart factories. Smart factories combine the newest technologies, such as collaborative robots (cobots) to provide a more flexible and responsive manufacturing process.

Ranging between Traditional Automation and Smart Factories:

Some of the factors that contribute to the transition to smart factories are the necessity to approach a higher level of product customization, shorter production times, and efficiency. At the center of this shift is are collaborative robots, which allow manufacturers to fulfill these aspirations without compromising the safety of the work environment.

It is important to note that some of the key characteristics of smart factories are:

- Adoption of sophisticated robotics and automation.

- Improved analytics of data to make decisions.

- Better adaptability and reactiveness to evolving production requirements.

- Harmless cooperation between humans and robots.

The most significant contributors to the Robotics Revolution:

Technological development, the evolution of the workforce population, and the necessity to be more efficient and flexible are the main forces behind the robotics revolution in the manufacturing industry.

The main drivers are:

- Both robotics and AI are developing in new technologies.

- Shifting the demographics of the work force and the requirements of skilled workers.

- The necessity of more flexibility and efficiency in the manufacturing.

The role of collaborative robots and factory automation will become more relevant as the production process is continually changing. Knowing the main driving powers of this revolution, manufacturers are in a better position to navigate around the evolving scenario and take advantage of the opportunities that the smart factories offer.

Learning about Collaborative Robots in Manufacturing:

The collaborative robots are re-defining the future of manufacturing as they cooperate with the human workers. The new generation of robot is also meant to be more productive, safer, and more flexible in the manufacturing process.

What Sets Cobots Apart:

Cobots are very different to the conventional industrial robots in their designs and capabilities. In contrast to traditional robots, which are usually large, complicated, and isolated due to their risks to the safety of human employees, cobots are designed to be small, easy to operate, and safe to operate with human operators. The main characteristics of cobots are higher safety sensors, user-intuitive programming interfaces and multitasking capabilities. All these features allow considering cobots a good alternative of manufacturers seeking to automate their operations without having to install a lot of safety fences.

Applications and Success stories in the real world:

A wide range of manufacturing sectors, including automotive and aerospace, electronics and consumer goods are being successfully integrated with cobots. As an example, in assembly lines, cobots may be employed to weld, check, and sort materials. One such well-known case is BMW who employ cobots in their factories to help employees with activities such as assemblies and quality inspections. Not only are these applications efficient but they also promote the safety of workers by performing repetitive or dangerous work.

Considerations of benefits and ROI:

Cobots have a number of advantages such as productivity, lower labor expenses, and quality of products. Also, cobots can make manufacturers have a faster return on investment (ROI) because of their simplicity and adaptability. When it comes to the application of cobot technology, the manufacturing companies must consider issues like production requirements, complexity of tasks, as well as the training needs of the workers. In this way, they will be able to utilize the cobot integration to the fullest and attain a substantial ROI.

Conclusion: Future of Human-Robot Cooperation in Factories:

The further development of Smart Factories is likely to be determined by further adoption of collaborative robots, or cobots, in the fabrication process, which will advance the concept of the Smart Factory.

With the development of Manufacturing Technology, we are likely to witness even more sophisticated robots in production processes that will improve efficiency and safety of workers.

The successful use of these technologies is in continuous innovation, extensive training processes and need to adjust to the new production requirements.

Through human-robot cooperation, the manufacturers will be able to open the doors to a new realm of productivity and competitiveness, which will result in growth and prosperity in the ever-complicated international market.

FAQ:

What do collaborative robots (cobots) mean and what do they mean in comparison with the conventional industrial robots?

Cobots or collaborative robots are meant to operate in synergy with human workers increasing the abilities and efficiency of the latter. Cobots are designed to be safe and user-friendly and located unlike the traditional industrial robots, which are usually isolated because of their safety, which means that the manufacturing process can be more integrated and collaborative.

What are the major advantages of introductions of cobots in manufacturing?

The most significant advantages of the use of cobots in manufacturing are the increased flexibility, cost-reduction, and safety of workers. Productivity and efficiency can also be enhanced by Cobots, and the manufactures can react promptly to the production needs.

What can manufacturers do to make sure that workers are safe when they adopt cobots into their processes?

To help manufacturers guarantee the safety of workers, they should perform a comprehensive risk evaluation, undertake mitigation measures, and train workers on how to cooperate with cobots in a safe and efficient way. There should also be adherence to regulatory standards and compliance requirements.

What type of training is needed in the case of human-robot collaboration?

Human-robot collaboration training is usually performed by teaching the workers on how to deal with cobots safely, learn about their abilities and restrictions, and react to any possible dangers or failures.

How do manufacturers who have applied the cobot technology perform in terms of cost and time savings?

The ROI of the manufacturers adopting cobot technology may be substantial, and the benefits comprise better productivity, less spending on labor, and better quality of the products. The specific application, industry and manufacturer among other factors will determine the exact ROI.

Does it have regulatory requirements on the use of cobots in the manufacturing process?

Indeed, there are regulatory norms governing the use of cobots in the manufacturing process, including safety and compliance norms. These standards are obligatory to manufacturers so that they can provide employees with safe working conditions.