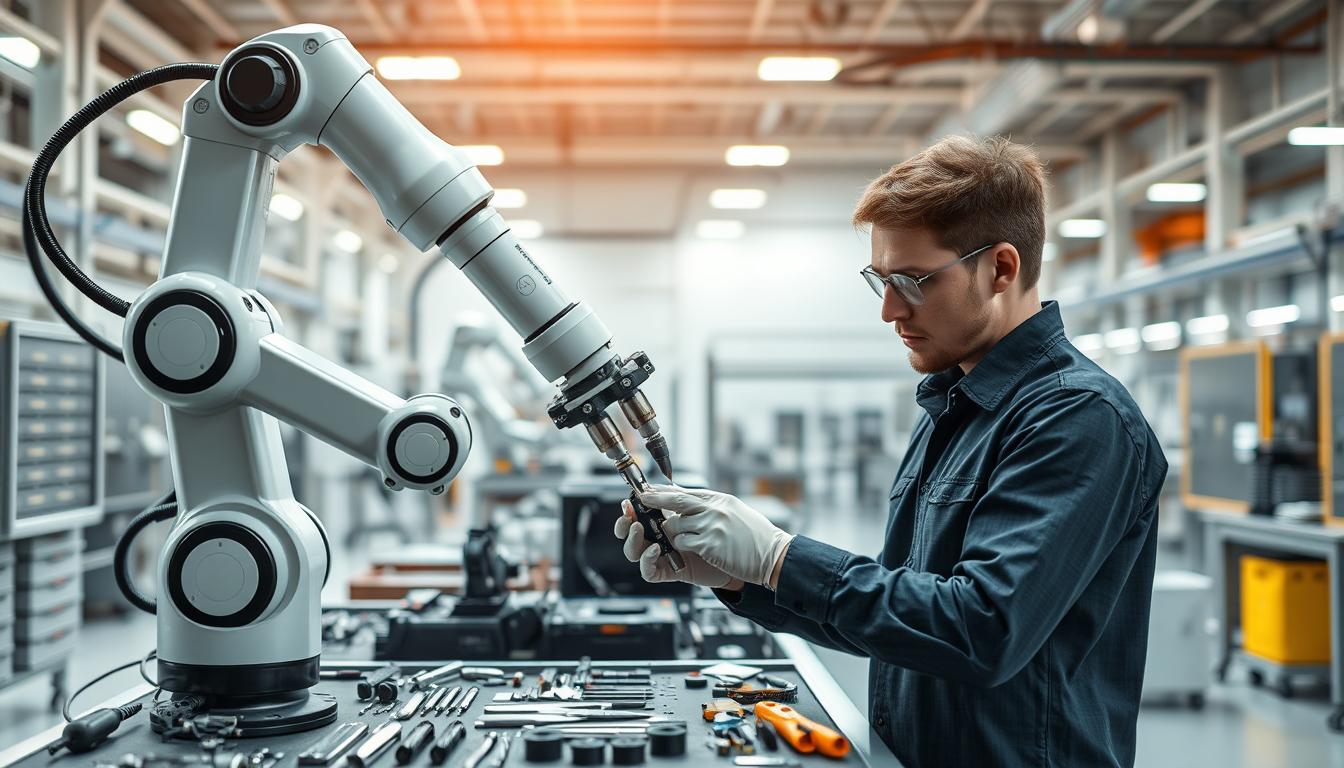

The world of production is also changing tremendously with the introduction of Human-Robot Collaboration. The conventional industrial robots are also becoming collaborative robots, also known as cobots, which are intended to work in collaboration with humans as we move into the year 2025.

The manufacturing technology industry is undergoing a transformation and this allows companies to boost their productivity and efficiency. Companies can use cobots to automate repetitive jobs, enhance the quality of products, and also minimize costs by introducing them into production lines.

The future of production is solely cooperation between man and robot and it is thrilling to consider what possibilities are going to arise due to the cooperation between the two entities.

Key Takeaways:

- The situation with Human-Robot Collaboration is changing the world of production.

- The cobots will be made to cooperate with people increasing productivity and efficiency.

- Introduction of cobots to production lines will also be able to automate the repetitive tasks and enhance product quality.

- It is all about the cooperation between robots and people in the future of production.

- Businesses have the advantage of lowering the cost and efficiency.

- The developement of Industrial Robots to Collaborative Cobots.

With the introduction of collaborative robots, also known as cobots, the manufacturing environment is likely experiencing a major shift in the way human and robot will work together in the future. This change can be motivated by demand to have more flexible and adaptable systems of production.

Conventional Automation: Abilities and constraints:

Such tools as industrial robots have found wide application in the manufacturing industry due to their accuracy and efficiency. They are limited however, in the sense that they are bound by cages or limited space in order to prevent injuries. Such restrictions interfere with their effectiveness of working together with human workforce.

What is different about Cobots Compared to Traditional Robots:

Cobots will be able to work with humans and increase the output and flexibility in the production space. The major differences are their capability to work without safety cages, enhanced sensors to detect existence of people, and programming to enable easy inclination into different tasks.

- Better safety provisions to collaborate with humans.

- Task flexibility and program flexibility.

- Learning and adaptation skills.

Influential Technologies that make Human-Robot Teams:

Some of the technologies that are propelling the efficacy of cobots are high robotics, AI, as well as machine learning. The technologies allow cobots to learn and react to the surrounding, hence they will be invaluable in the contemporary manufacturing.

Key technologies include:

- Intense sensor feedback mechanisms.

- Adaptive task management machine learning algorithms.

- Easy-to-use program interfaces.

How to Revolutionize Manufacturing with Human-Robot Collaboration:

The collaboration of humans and robots in manufacturing is changing the world of manufacturing, providing high flexibility and productivity never before seen. The benefits are becoming more evident as industries keep adopting this technology. Making the use of cobots in the manufacturing lines, manufacturers would be able to use the advantages of both the human labor force and the robotic system.

Shared Workspaces Ideas of Safety:

The safety features introduced into the development of cobots make them capable of working with humans without the common safety barriers. Cobots have advanced sensors and collision detection systems that stop or reduce their movement when they detect a human presence, and this makes the workplace safe.

Complementary Capability Productivity Gains:

The robotic precision combined with the human dexterity results in a high level of increased productivity. Repetitive or heavy work can be done by cobots and human workers are free to deal with complex assembly, quality control, and other jobs that cannot be done by robots and demand delicacy and judgment.

The 2025 Production Line Applications in the Industries:

Cobots will be used in different sectors such as automotive, electronics and healthcare by the year 2025.

Human-Robot Collaboration:

Cobots can be reprogrammed and repurposed easily due to their versatility, which means that they can be considered an appealing option to manufacturers trying to future-proof their operations.

| Industry | Application | Benefit |

| Automotive | Assembly and welding | Increased precision and reduced labor costs |

| Electronics | Component handling and inspection | Enhanced quality control and flexibility |

| Healthcare | Medical device assembly and packaging | Improved safety and compliance with regulations |

Skills and Training of the Cobot Age Workforce:

Since the use of cobots is on the rise, the importance of training of workforce remains crucial.

The skills required by employees will require some skills that are complementary to robotic abilities like programming, maintenance and supervision of cobots. This trend raises the significance of upskilling and reskilling interventions in manufacturing entities.

Findings Conclusion: The Future of Collaborative Manufacturing:

The use of cobots in the manufacture industry is transforming the production lines, increasing safety, and improving productivity. With the prospects of a human-robot collaboration in the coming 2025, the possibilities of how the industry may evolve are enormous. Manufacturers have the option to automate work with the help of cobots but use human expertise, which will help to achieve a more efficient and versatile production process.

This is the future of manufacturing, and there will be further innovations in automation and training of the people. Manufacturers are able to remain competitive by embracing cobots, enhance the quality of their products and adapt to the shifting market conditions. With the changing manufacturing environment, the collaboration between humans and robots will be very essential in developing a more efficient and productive industry.

FAQ:

What is the human robot collaboration on production lines?

Cobot collaboration Human-robot collaboration, or human-robot working together, is a practice whereby robots and human beings collaborate in the same working environment, which improves both the efficiency and productivity of manufacturing.

The cobots are intended to be more flexible, safe, and versatile to enable them to operate in collaboration with people without having to install a large safety barrier, as compared to the old-fashioned industrial robots who are usually isolated and enclosed in a separate area.

What are the advantages of human-robot partnerships in the industrial world?

It has advantages in better safety, higher productivity, greater flexibility, and better quality of products, since human beings and robots can offset the capabilities of one another.

Which safety measures were undertaken in collaboration between humans and robots?

Advanced sensors, collision detection, lightweight robot designs that have minimized the risk of injury, training programs of workers to handle cobots safely are some of the safety innovations.