Space-Based Manufacturing: What You Need To Know. As we look to the future, a big question is: Can space-based manufacturing change how we make things? Can orbital production in space really change the game?

The idea of a zero-gravity industry is no longer just a dream. Experts say space manufacturing could be a substantial economic boost, and predict it could be worth over $10 trillion.

Key Takeaways

- The zero-gravity industry is expected to drive significant economic growth.

- Space-based manufacturing offers unique production opportunities.

- The value of space manufacturing could reach $10 trillion.

- Orbital production is set to change traditional making things methods.

- Advances in space manufacturing are key for the in-space economy.

The $10 Trillion Frontier: Space-Based Manufacturing

Space-based manufacturing is a new and exciting field, and it’s expected to be worth $10 trillion. This growth is thanks to new technology and lower launch costs, attracting investors and companies.

Current Market Valuation and Projections

The value of space-based manufacturing is growing fast. Companies like Space Forge and Varda Space Industries are leading the way, using new technologies, such as in-situ resource utilisation.

Market Projections: Experts think the market will continue to grow because more advanced manufacturing technology is being applied in space.

| Year | Market Valuation | Growth Rate |

|---|---|---|

| 2023 | $1 Billion | – |

| 2025 | $5 Billion | 500% |

| 2030 | $10 Trillion | 200,000% |

Investment Landscape

Investment in space-based manufacturing is improving, with both governments and private companies showing significant interest and allocating substantial funds for research and development.

Key areas of investment include research, infrastructure, and technological advancement, which are receiving considerable financial support.

The Zero-Gravity Advantage: Why Manufacture in Space?

Space’s zero-gravity environment offers unique opportunities for manufacturing, transforming various industries. It enables the creation of materials and products that are difficult or impossible to produce on Earth.

Physics of Microgravity Production

In space, fluids and gases behave differently than on Earth. This allows us to create special materials and products. Microgravity production enables the growth of crystals with improved qualities, which are very useful in electronics and medicine.

Material Properties Unique to Space Environments

Space-based manufacturing can create materials with unique properties. For example, some alloys and composites made in space have special qualities, which are highly sought after for advanced uses.

| Material | Earth-Manufactured Properties | Space-Manufactured Properties |

|---|---|---|

| Crystals | Limited purity and size | Higher purity and larger size |

| Alloys | Variable composition | Uniform composition |

| Composites | Limited structural integrity | Enhanced structural integrity |

Cost-Benefit Analysis of Orbital Manufacturing

Starting a space manufacturing venture requires significant initial investment. However, a cost-benefit analysis indicates substantial long-term gains, and the ability to produce high-value materials and products in space is highly attractive to investors.

The advantages of zero-gravity manufacturing include the creation of materials with unique properties. This process also leads to improved product quality and considerable investment returns. and as the industry expands, the benefits are expected to increase even further.

Unique Benefits of Orbital Production

Space-based manufacturing is opening up new possibilities in production quality and efficiency. The space environment offers advantages not found on Earth.

Superior Material Characteristics

Manufacturing in space creates materials with superior characteristics. For example, microgravity helps make crystals and materials with fewer defects and better structure.

NASA and other space agencies have found that materials made in space are more durable. They have enhanced properties due to the lack of gravity-related stresses during production.

Purity and Structural Integrity

The microgravity of space also helps produce goods with higher purity and structural integrity. For instance, pharmaceuticals made in space have enhanced efficacy because of their uniform structure.

“The unique conditions in space allow for the creation of pharmaceuticals with improved crystal structures, leading to more effective treatments.”

This is very important in the pharmaceutical industry. The purity and structure of drugs can greatly affect their effectiveness.

Energy Efficiency in Space

Orbital production also has the chance for energy efficiency. Space manufacturing can use renewable energy like solar power, which reduces the need for traditional energy sources.

Also, recycling and reusing materials in space can cut down waste, which reduces the energy needed for manufacturing operations.

Who’s Leading the Space Manufacturing Race?

The space manufacturing industry is rapidly expanding. Numerous companies are leading the way and collaborating with governments to shape the future.

Pioneering Companies and Their Technologies

Space Forge and Varda Space Industries are at the forefront of developing new technologies for manufacturing products in space. For instance, Space Forge is focused on creating advanced satellites, while Varda Space Industries is dedicated to producing medicines in space.

Government and Private Sector Collaboration

Governments and private companies are collaborating to drive innovation. NASA and other agencies are partnering with companies, which helps share resources and accelerate technology development.

According to a report on In-Space Manufacturing, this collaboration is key to the sector’s growth.

Industries Set for Space Manufacturing Transformation

Space manufacturing is changing the game for industries like pharmaceuticals and advanced materials. The unique conditions in space are driving innovation and growth in these sectors.

Pharmaceuticals and Biotechnology

In space, microgravity helps make high-quality proteins and crystals for drug research. For example, Merck is working with the International Space Station to make proteins in zero-gravity, which could lead to new drug breakthroughs.

This could help find cures for diseases that are hard to treat now.

Advanced Materials and Semiconductors

Space manufacturing creates advanced materials with special properties, like better semiconductors. Without gravity, materials can have fewer defects and be more uniform.

Companies are looking into using space to produce high-quality semiconductors, which could significantly transform the electronics industry.

Optical Fibres and Communications

Making optical fibres in space can lead to better quality and transmission. This could make global communication networks faster and more reliable.

As we need faster data transfer, space-made optical fibres could really change the communications world.

Additive Manufacturing and 3D Printing

Additive manufacturing and 3D printing in space can make complex parts with great precision. This is great for making parts for spacecraft and creating materials that can’t be made on Earth.

Adding additive manufacturing to space manufacturing could bring significant changes to many industries, like aerospace and healthcare.

Factories in Space: Manufacturing Beyond Earth

Manufacturing in space is transitioning from science fiction to reality, driven by advancements in technology and an increasing interest in utilising space for production. It’s important to understand the current state of space manufacturing, its future prospects, and the plans for establishing space factories.

Current Operational Facilities

The International Space Station (ISS) is a vital hub for space-based research and manufacturing. While primarily focused on research, it has also facilitated the production of items in space, providing valuable insights into space manufacturing.

Near-Future Manufacturing Platforms

As the space industry grows, new manufacturing locations are emerging. Commercial space stations and specialised facilities are being planned to make space manufacturing more practical and efficient.

Long-Term Vision for Space Factories

The vision for space factories is to create large, sustainable manufacturing operations. These factories would produce a variety of goods, including medicines and components for space missions.

However, to achieve this goal, significant advancements in technology, construction methods, and overall execution are necessary.

Space manufacturing offers many opportunities for businesses across different sectors, including aerospace and materials science. As companies look for ways to stand out in this growing field, it is important to think ahead. By predicting future trends and new technologies, businesses can position themselves to stay competitive.

This proactive approach allows them to take advantage of the unique benefits of making products in space, such as creating materials with better qualities in microgravity. It also helps them adapt to the fast-changing market that is exploring new possibilities beyond Earth.

Early Investment Opportunities

Investing early in space technology can provide a significant advantage. Companies like Space Forge are already reaping the benefits of this approach by partnering with research groups to develop new technologies.

Key areas for early investment include advanced materials, in-orbit assembly, and sustainable space infrastructure. By concentrating on these areas, companies can take the lead in the space manufacturing revolution.

| Investment Area | Potential Benefits | Potential Challenges |

|---|---|---|

| Advanced Materials Processing | Creation of novel materials with unique properties | High development costs, regulatory hurdles |

| In-Orbit Assembly | Enhanced capabilities for constructing large-scale space structures | Technical complexities, high operational costs |

| Sustainable Space-Based Infrastructure | Long-term viability of space manufacturing operations | Significant upfront investment, logistical challenges |

Research and Development Partnerships

Working with research groups and other companies can speed up technology development. These partnerships help share knowledge, resources, and risks.

For example, teaming up with government agencies can combine public and private strengths, leading to innovation in space manufacturing.

Challenges and Solutions in Space Manufacturing

Space manufacturing is growing, but it faces many technical, logistical, and regulatory hurdles that must be overcome to unlock its promise fully.

Technical Hurdles

One major challenge is developing reliable manufacturing processes in space. The unique conditions of space, such as microgravity and extreme temperatures, are difficult to manage. Other challenges include;

- Developing materials and processes that can withstand the harsh conditions of space.

- Creating reliable and efficient manufacturing equipment that can operate in microgravity.

- Addressing the challenges of in-space assembly and integration of complex systems.

Innovative Solutions on the Horizon

Despite the hurdles, new solutions are being explored. Research and development partnerships between industry, academia, and government are pushing the field forward. Key areas include;

- Advancements in robotics and automation are making manufacturing more efficient.

- New materials and manufacturing methods are being developed for space.

- New business models are emerging to support the growth of space manufacturing.

Future Timeline: The Next Decade of Space Manufacturing

The next decade will be crucial for space manufacturing. We can expect significant progress in space manufacturing as companies and governments invest in new technologies.

These advancements will allow us to create various products in microgravity. Innovations like 3D printing, better materials, and automated assembly will help build complex structures, satellites, and even spacecraft in orbit.

This time will not only improve our abilities in space but may also change industries on Earth by providing new materials and manufacturing methods that we can’t achieve on the ground.

2025–2026: Establishing the First Commercial Orbital Manufacturing Facilities

Private companies begin operating small-scale factories in low Earth orbit (LEO), producing fibre optics, pharmaceuticals, and high-purity alloys. Early successes demonstrate the economic viability of in-orbit production.

2027–2028: Expansion of Additive Manufacturing in Space

3D printing capabilities have matured, enabling on-demand production of spacecraft parts, habitats, and repair components directly in orbit, reducing dependency on Earth launches.

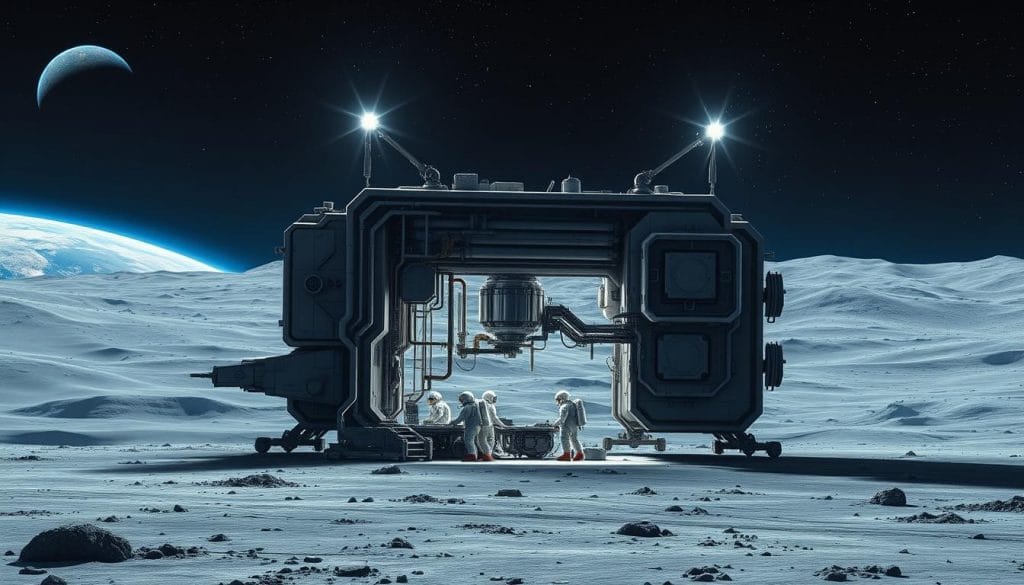

2029: Lunar-Based Manufacturing Begins

The first pilot projects on the Moon use in-situ resource utilisation (ISRU) to process regolith into building materials, paving the way for sustainable lunar infrastructure.

2030: Space Manufacturing for Medical and Biological Applications

Microgravity environments enable breakthroughs in growing human tissues, organs, and advanced biomaterials, revolutionizing healthcare applications on Earth.

2031–2032: Large-Scale Assembly of Spacecraft and Solar Power Satellites

Automated assembly lines in orbit begin constructing massive structures, including solar power satellites capable of beaming energy back to Earth.

2033–2034: Asteroid Mining and Resource Processing

The first operational asteroid mining missions return raw materials to orbital manufacturing hubs, supplying rare metals and water for fuel production.

2035: Fully Operational Off-Earth Industrial Supply Chains

An integrated network of orbital, lunar, and deep-space facilities produces goods entirely off-Earth, marking the transition to a sustainable space economy.

Conclusion: Key Takeaways for the New Industrial Frontier

The space manufacturing industry is ready to boost the economy and drive innovation in space exploration and technology. Important factors for the success of this industry include the need for early investment, building strategic partnerships, and creating a strong regulatory framework.

Recent improvements in reusable rocket technology have lowered the cost of launching satellites. This cost reduction has helped increase the number of satellite networks, like Starlink and Galileo. For more information about the space industry, you can visit SpringerLink.

The space manufacturing sector is growing and is expected to be important for the overall economy. It’s crucial for all stakeholders to understand the key points of this industry so they can take advantage of the many opportunities it offers.

For more articles on Space, please follow the link